Auto parts, aircraft high-speed rail case

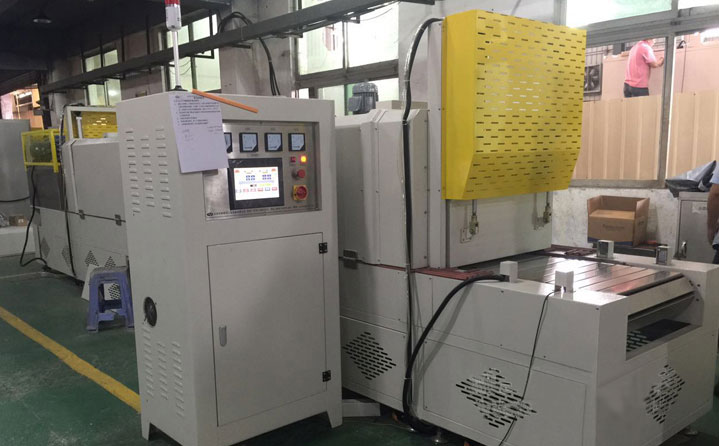

Roasting car hub tunnel drying furnace

ⅠMain technical parameters of the tunnel drying furnace with roasting car wheel hub

1、Inner size:Drying area,L4800*H300* Feeding wide700mm;

2、External dimension (about) : the total length of the drying furnace is 8100mm(including the connecting platform)* total height is 1520mm* total width is 1100mm,the height from the ground to the network belt is 800mm, the feed width of the product is 700mm, and the feed height is 300mm adjustable (equipped with automatic lifting door front and rear).the drying part has a total length of 4800mm and is equipped with automatic lifting door at both ends of the buffer zone of 300mm, the cooling zone of 1200mm, the feeding part of 600mm, and the lifting and connecting platform of the discharging part of 700mm.

3、Temperature range:Normal temperature~'250℃可调adjustable;

4、the precision of the instrument:≤±0.1℃;

5、temperature fluctuation degree:≤±1℃

6、temperature uniformity:≤±5℃;

7、Heating rate:≤8℃/min;

8、Air transport mode: circulation on three sides;

9、Shell temperature:Shell temperature is not higher than room temperature ' 15 ℃, seams and the oven temperature is not higher than room temperature ' 25 ℃; 10、Power supply: three-phase five-wire system, 380V, 50HZ;

11、Total power: 18KW;

ⅡStructural features of the tunnel drying furnace of roasting automobile wheel hub

1、Shell material: made by bending and welding of 2mm thick cold rolled plate (best comprehensive performance of strength, plasticity and welding);

2、Furnace bottom frame: it is made by adopting the square method of 50*50*1.5mm, maintaining the bearing strength of each internal and external surface of the furnace and retaining the heat expansion and cold shrinkage coefficient to prevent furnace deformation.

3、Thermal insulation material: 100K encrypted aluminum silicate rock wool with characteristics of non-combustible and strong heat insulation, with thickness of 100mm; 4、Electric cylinder: built-in electric cylinder of the furnace body drying part;

5、Driving part: stainless steel chain plate driving, driven by 0.37kw Taiwan yongkun stepping motor;

6、Cooling part: the shell of the cooling part is made of 2mm thick stainless steel plate 201#. Two 0.37kw centrifugal fans are installed on the cooling section with one industrial refrigerator.

7、Foot cup/castor: the bottom is equipped with adjustable foot cup, which is convenient for the chamber body to adjust the height of the chamber body;

Ⅲ The control system of the tunnel drying furnace of the wheel hub of the drying car

1、Air motor: equipped with Taiwan adeli 0.37kw air motor;

2、Wind wheel: equipped with 9 "201# stainless steel multi-wing air wheel;

3、Radiant heating: heating pipe adopts 201# stainless steel heating pipe to control heating with heat sink;

4、Control of heating tube: control each group of heating tube by SSR solid relay;

5、Temperature sensor: omron 3-meter standard, k-type thermocouple;

6、Others: imported schneider and Japanese omron are used for controlling the electrical equipment;

Ⅳ The environmental conditions of the tunnel drying furnace with roasting wheel hub

1、The environment temperature:-5℃~'40℃;

2、Relative humidity:≤85%RH;

3、Power supply:AC380V±10%,50Hz;

Ⅴ Training of the tunnel drying oven with the wheel hub of the car

Free technical training